Summary

High-Frequency Pressure Cycling System

Sensata’s standard pressure-cycling operated at <10 Hz, making a 400-million-cycle qualification test a 462-day effort that consumed >$500k in testing resources. I developed a pressure cycler capable of 5 kHz, reducing that same test to under a day and bringing the cost down to roughly the $10k NRE for the setup. Scaled across the hundreds of pressure-sensor validations performed each year, the system represented millions in potential savings.

Using the same piezo actuator, I extended the platform to run mechanical resonance and frequency-response analysis, allowing Sensata to empirically determine true mechanical transfer functions for their sensors for the first time (see below).

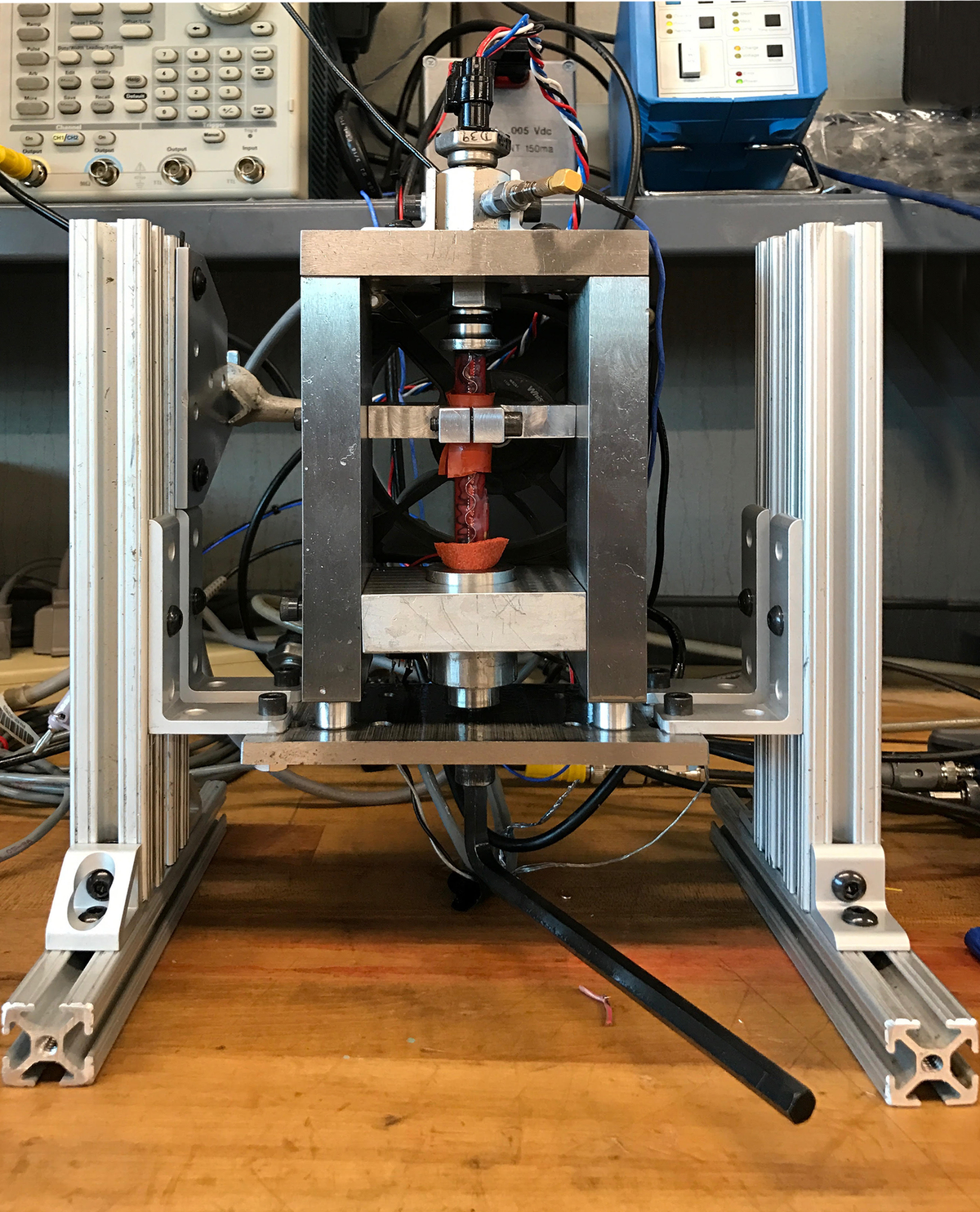

Photos

Fig. 1: Full system in use, visuals of the oscilloscopes, amplifier, electromechanical-fluidic system, and the key innovation of a fluid accumulator that would bleed small amounts of fluid into the system via a repurposed snubber to replenish fluid leaking out past the dynamic piston seal. The snubber served as a pressure barrier, so, despite cycling rapidly on the system side, it would create an artificial pressure wall due to the significant L/d ratio of the micro-orifice. See Pouiseuille’s Law for more details.

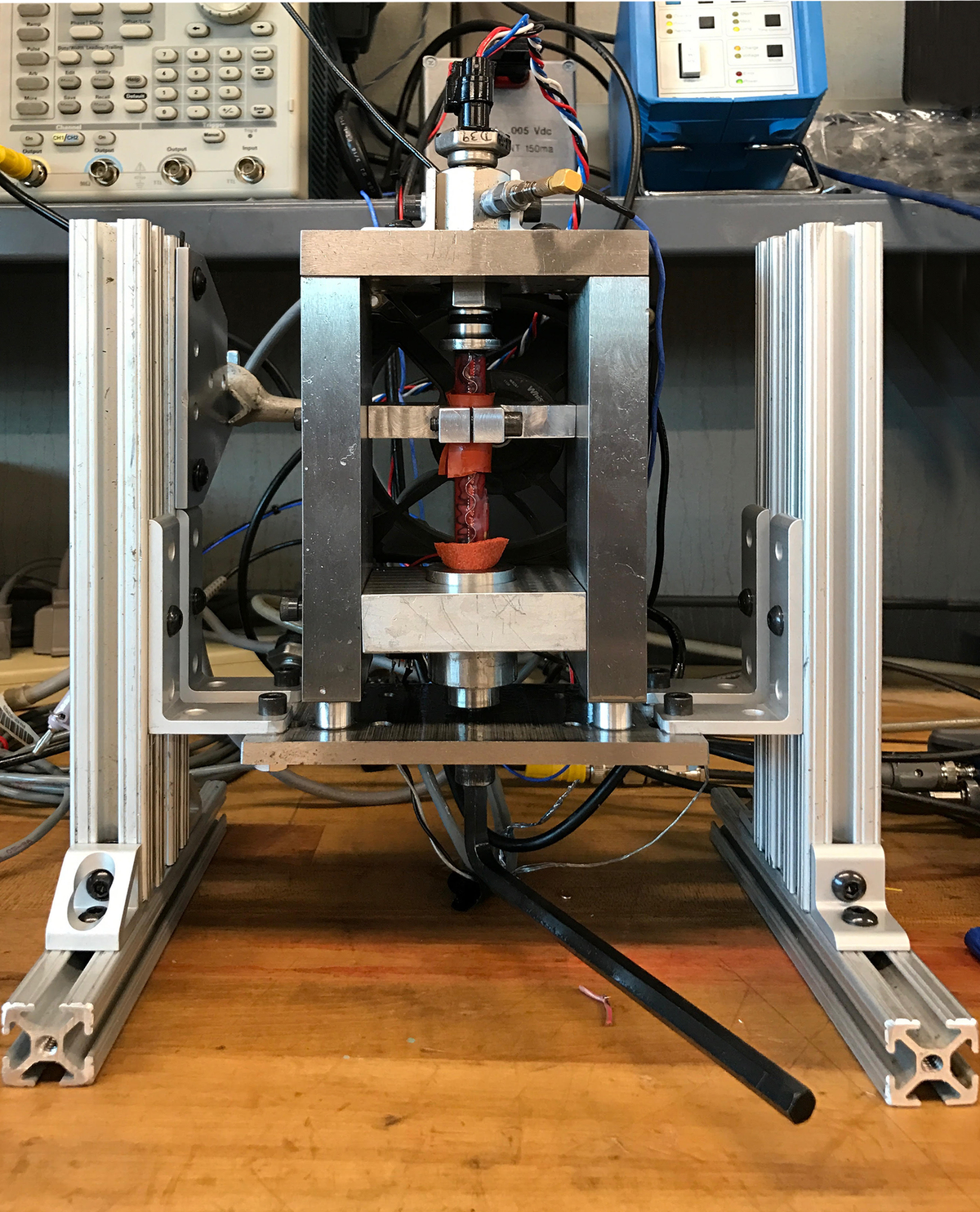

Fig. 2: Close-up of the pressure cycler interface, a 120um displacement stack of ceramic piezoactuators was used to mechanically actuate a piston, displacement induced by 10kV amplitude sine wave. The piston would repeatedly compress a small volume of fluid which the pressure sensor under test and the Kistler reference pressure would simultaneously measure.

Fig. 2: Close-up of the pressure cycler interface, a 120um displacement stack of ceramic piezoactuators was used to mechanically actuate a piston, displacement induced by 10kV amplitude sine wave. The piston would repeatedly compress a small volume of fluid which the pressure sensor under test and the Kistler reference pressure would simultaneously measure.

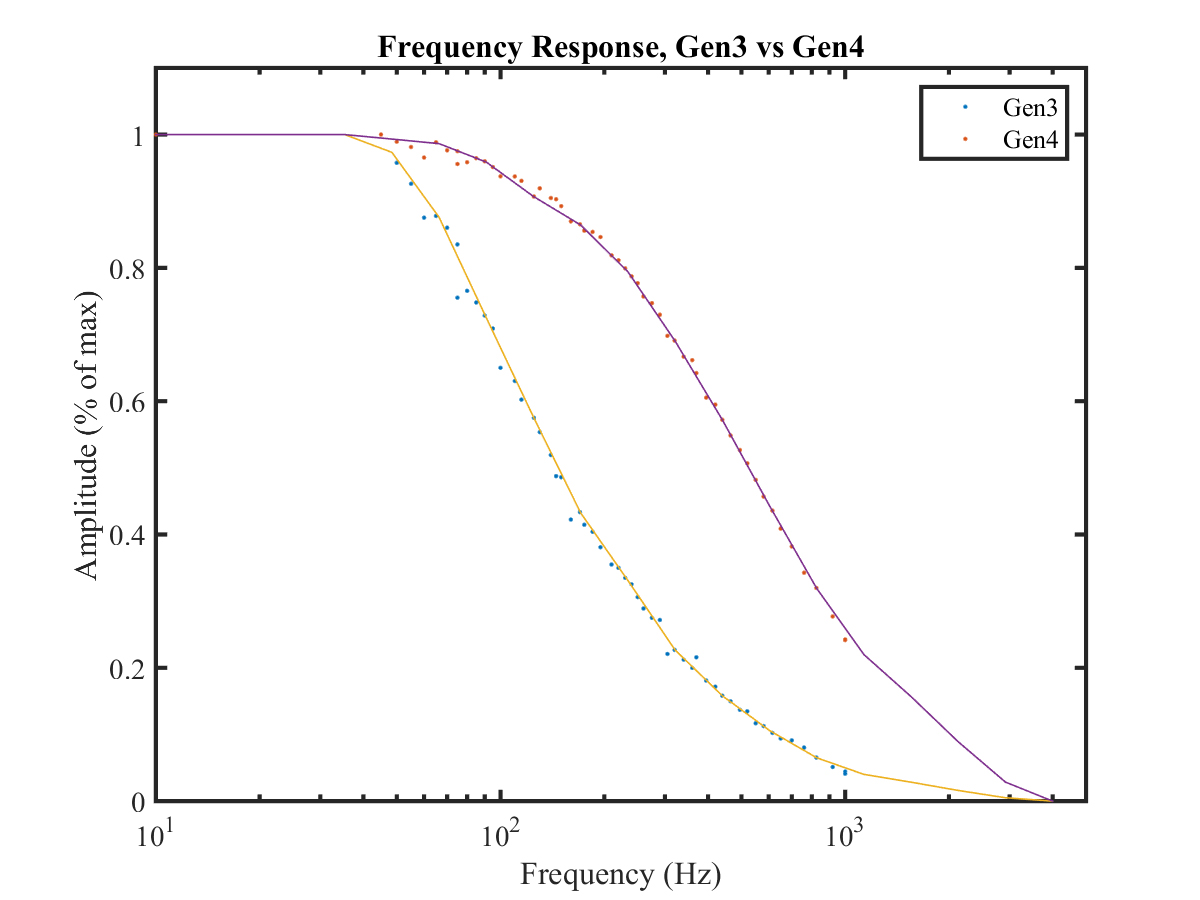

Fig. 3: Following the poster session, I spent time conducting additional testing to gather enough data to normalize the sensor outputs. Each dot on this plot represents a discrete sampling at a particular frequency. A Fast Fourier Transform is conducted on each subset of data at every frequency tested, and the aggregate of every transform is plotted here using a MATLAB script. The digital filtering (Low Pass Filter emulation) built into the ASIC of the Gen4 sensor dampens response compared to the Gen3 ASIC that does not have this feature.

Fig. 3: Following the poster session, I spent time conducting additional testing to gather enough data to normalize the sensor outputs. Each dot on this plot represents a discrete sampling at a particular frequency. A Fast Fourier Transform is conducted on each subset of data at every frequency tested, and the aggregate of every transform is plotted here using a MATLAB script. The digital filtering (Low Pass Filter emulation) built into the ASIC of the Gen4 sensor dampens response compared to the Gen3 ASIC that does not have this feature.